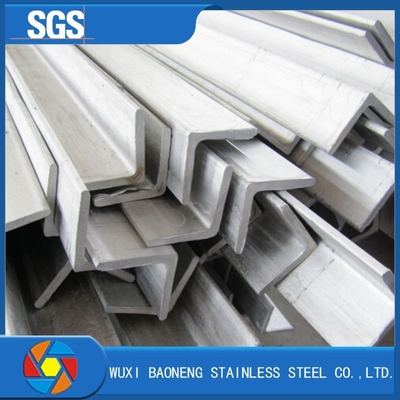

1.431 1.4325 1.4871 Stainless Steel Angle Bar 304 316 321 310 Equal Cold Rolled Angle Bar

| Place of Origin | CHINA |

|---|---|

| Brand Name | TISCO, ZPSS, BAOSTEEL, POSCO, JISCO, LISCO, etc |

| Certification | mill certificate |

| Model Number | 410S stainless steel angle bar |

| Minimum Order Quantity | 25T |

| Price | negothiable |

| Packaging Details | Export Package |

| Delivery Time | 15-20 days after deposit |

| Payment Terms | L/C, T/T |

| Supply Ability | 2000T PER MONTH OR MORE |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Width | 20-610mm | Technique | Hot Rolled |

|---|---|---|---|

| Surface Treatment | Polished | Grade | 300 Series |

| Processing Service | Bending, Welding, Cutting | Surface Finish | BA, BA |

| Application | Construction | Steel Grade | 316, 321, 304 |

| Length | 6-12m | ||

| Highlight | 1.4325 Stainless Steel Angle Bar,1.4871 Stainless Steel Angle Bar,1.431 stainless steel equal angle |

||

410S stainless steel angle bar

Type 410S is a low-carbon, non-hardening ferritic stainless steel. The low carbon and a small alloy addition minimize austenite formation at high temperatures which restricts the alloys ability to harden. 410S remains soft and ductile even when rapidly cooled from above the critical temperature. This non-hardening characteristic helps prevent cracking when the alloy is exposed to high temperatures or welded. 410S is completely ferritic in the annealed condition. It exhibits adequate corrosion resistance similar to 410 and good oxidation resistance.The ability to cool from elevated temperatures without hardening makes type 410S suited to applications such as annealing boxes, quenching racks, oxidation-resistant partitions and other high-temperature units.

APPLICATIONS

Petroleum refining and petrochemical processing, columns, distillation trays, heat exchangers, towers, ore processing, mining machinery, thermal processing, annealing boxes, partitions, quenching racks, gate valves, press plates

ElementType 410S (Wt.%)

Carbon: 0.08 max

Manganese: 1.00 max.

Phosphorus: 0.040 max.

Sulfur: 0.030 max.

Silicon: 1.00 max.

Chromium: 11.50-13.50

Nickel: 0.60 max

Titanium: 0.20 max

Element (Wt.%)

| Carbon | Manganese | Phosphorus | Sulfur | Silicon | Chromium | Nickel | Titanium |

| 0.08max | 1.00max | 0.040max | 0.030max | 1.00max | 11.50-13.50 | 0.60max | 0.20max |

Surface Treatment

| Surface Treatment | Definition | Application |

| NO.1 | A hot - rolled piece whose surface has been treated by heat treatment, pickling or the corresponding process | Chemical Tanks, Pipes, Chemical Industry Equipment etc. |

| 2B | After cold rolling, heat treatment, pickling or other equivalent treatment, the final cold rolling to give appropriate luster | Medical Equipment, Food Industry, Construction Material, Kitchen Utensils etc. |

| BA | After cold rolling, bright heat treatment is given | Kitchen Utensils, Electric Equipment, Building Construction etc. |

| NO.4 | Products polished with abrasives 150 to 180 as specified in JIS R6001 | Kitchen Utensils, Building Construction, Medical Equipment etc. |

| HL | After polishing, use the appropriate abrasive size to form a continuous polishing streak | Building Construction etc. |

| 8K | A mirror-like reflective surface given by polishing with finer abrasives over 800 mesh | Reflector, Mirror, Interior and exterior decoration etc. |

FAQ

Q1:What product information must I provide before making a purchase?

Q6:Do you offer a service for customized products?